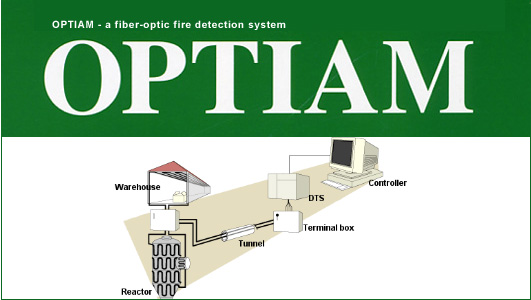

Designed for factories and plants, this next-generation disaster-prevention system detects unusual changes in temperature, to prevent fires before they can happen.

Advantages include:

・Simple structure allows easy maintenance, and thus low running costs.

・Highly resistant to high temperature, humidity, dust, and corrosive gases, and so can be placed in any location.

・Measures changes in temperature at one-meter intervals, allowing accurate pinpointing of fire locations.

・Monitors placed in control rooms, etc., allow concentrated observation. Can be operated with minimum manpower.

・Detection is carried out using light as a medium, which is not affected by electromagnetic interference. Thus, OPTIAM is ideal for monitoring inside electric power cable ducts.

・OPTIAM is inherently explosion-resistant, enabling it to be installed in dangerous places.

Theory of temperature and position measurement

A laser pulse is sent through the optic-fiber cable from one end. As the pulsed radiation passes through the fiber, it produces backscattering according to the temperature. Temperature information is measured according to the strength of the backscattering, and distance is measured by the time taken for the backscattering signal to arrive. In effect, the optical fiber acts as a sensor, meaning that the structure, and thus maintenance, is simple.

Optical fiber/loop detection

By measuring through sending laser pulses alternately from either end of the optical fiber, detection accuracy is drastically improved, even over large distances. Furthermore, in the unlikely event that the optical fiber is cut, the system automatically continues monitoring, meaning that no areas are left unmonitored.

Multi-stage alarm output

With previous sensors, alarms are not issued until the temperature at areas surrounding the sensors reaches around 70°C. Also, because sensors are installed in the ceiling, by the time the alarm was activated, the fire has taken hold of the floors and walls in many cases. On the other hand, with OPTIAM, the temperature at which alarms are activated can be pre-programmed to any desired set of temperatures (example: 40°C, 50°C, and 70°C), and can be set to issue alarms at multiple levels. Thus, even the smallest fire is detected by OPTIAM.

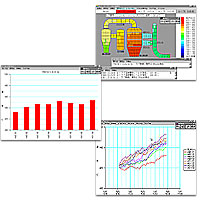

Highly functional graphic software

Monitor temperature distribution at 1-meter intervals in real time using the color display. Because the location of any abnormalities can be pinpointed very accurately, fires can be detected before they erupt, and in the event of a fire, information needed for fire-fighting can be grasped and relayed effectively. The structure is simple – one optic-fiber cable to be laid.

Special heat-resistant optical fiber

Optical fibers in an SUS (stainless steel) pipe are operable in temperatures ranging between -50°C and 350°C. Naturally there is no effect from electromagnetic induction, something that can be a problem with electric temperature sensors.

Tunnels/utility tunnels

Utility tunnels such as road and rail tunnels carry an increasing number of lifelines such as power and telephone lines. The main disaster-prevention function of these tunnels is to pinpoint the location of major infrastructure abnormalities. Because OPTIAM is able to measure temperature changes at 1-meter intervals, emergency situations can be located easily.

Electric power equipment

One of the main problems with fire prevention for electric power equipment is that the devices are often unmanned. Also, electromagnetic waves resulting from high voltage can adversely affect sensors. However, OPTIAM performs remote monitoring without interference from electromagnetic waves.

Buildings/multi-story car parks

Buildings are becoming taller and bigger, thus increasing the fire risk. However with OPTIAM, centralized monitoring from a control room is possible, thus reducing the manpower spent on disaster prevention. OPTIAM is also ideal for multi-story car parks, which are often unattended at night.

Specifications

●DTS main body

| Models | DTS200 | DTS400 | DTS800 | DTS-LR | DTS-ULR |

|---|---|---|---|---|---|

| Measurement method | Semi-loop type | Loop type | Loop type or single-end type | Single-end type | |

| No. of channels | 1 channel | 1 channel | 2, 4, or 6 channels (3 types) | 1-4 channels | |

| Measurable ranges | 1.5km | 2km | 4, 8, or 10 km (3 types) | 15km | 35km |

| Measurable temperature ranges | -100 to +400℃ | -200 to +600℃ | -200 to +600℃ | -100 to +300℃ | -20 to +120℃ |

| Measurement times | 10 sec. | 10 sec. | Setting 10 sec./channel or greater is possible | Approx. 60 sec. | Approx. 60 sec. |

| Distancce resolution | 3m | 1m | 1m | 3m | 5m |

| Minimum heating length | 5m | 2m | 2m | 5m | 8m |

| Temperature resolution | ±1℃ (60sec.) | ±0.5℃ (60sec.) | ±0.5℃ (60sec.) | ±1℃ | ±3℃ |

| External output | Arcnet (also adaptable to Ethernet) + RS232C | ||||

| Operating environment | 0℃ to +40℃ Humidity not exceeding 95% | +10℃ to +35℃ Humidity not exceeding 95% | |||

| Power consumption | 24 VDC, 20 W | 100 VAC, 50/60 Hz, 200W | |||

| Outer dimensions | 430(W) ×300(D) ×133(H)mm | 538(W) ×342(D) ×337(H)mm | 538(W) ×442(D) × 338(H)mm | ||

| Weight | 6kg | 28kg | 31kg | ||

| Remarks | For simple observations | The temperature resolution shown is the value of the loop type with 4 km measurement range and 60 seconds measurement time. (This value varies depending on the measuring method, measurement range, and measurement time.) | For measuring ultra-long distances | ||

●Optic fiber sensor

| High temperature type H | General-purpose type N | |

|---|---|---|

| Usable temperature range | -20℃ to +160℃ | -50℃ to +350℃ |

| Fiber stand | GI-50/125 Outer diameter 150 uM | GI-50/125 Outer diameter 250 uM |

| Stand coating | Specially processed organic coating | Specially processed organic coating |

| Armor | SUS304 Outer diameter 1.8mm | SUS304 Outer diameter 1.2mm |

| Tolerable flexural radius | 150mm | 50mm |

| Weight | Approx. 5kg/km | Approx. 5kg/km |

| Transmission band | 200 MHz and above | 200 MHz and above |